18/11/14 (Rohun)

Today I worked some more kinks out of the initial design of the Tesla-Gorlv design, as it is a tad tricky to design the slot assembly that we will use to put the turbine together. The design proved to be too small to print successfully, so I had to go in and increase the sizes of various parts in order to create stable printed pieces. I also started a correspondence with Bryan Kroh of Daedalus who will attempt to help me run a flow simulator on the turbine to see how water would flow across the blades.

(Elizabeth) Today I created three basic turbine models to be printed: a Darrieus, Savonius, and a Gorlov. The idea is that we can test and compare our design idea to these turbines to see what about our turbine is working, and what about it is not working. I also created some drawings for the modification of a gutter, with one side open (but still covered in a plexi material) that will be built this weekend.

19/11/14 (Rohun)

I managed to get the Soldiworks FloXpress simulator working, which will give us deeper insights as to the nature of the flow of the water through the turbine, and I printed a second iteration of the tesla core for the turbine. I also worked with Bryan Kroh of Daedalus to figure out how to sweep a base along a helix.

3/12/14 (Rohun)

I created and the finalized a schedule for getting things turned in on time, I also modified, printed, and then tested a version of the Tesla core that was able to spin significantly faster than the initial design. As a group, Elizabeth and I created a tutorial on the FloXpress plugin for Solidworks. We also discussed various classes that we might take at Techshop (the milling SBU, the injection molding class, and the welding class)

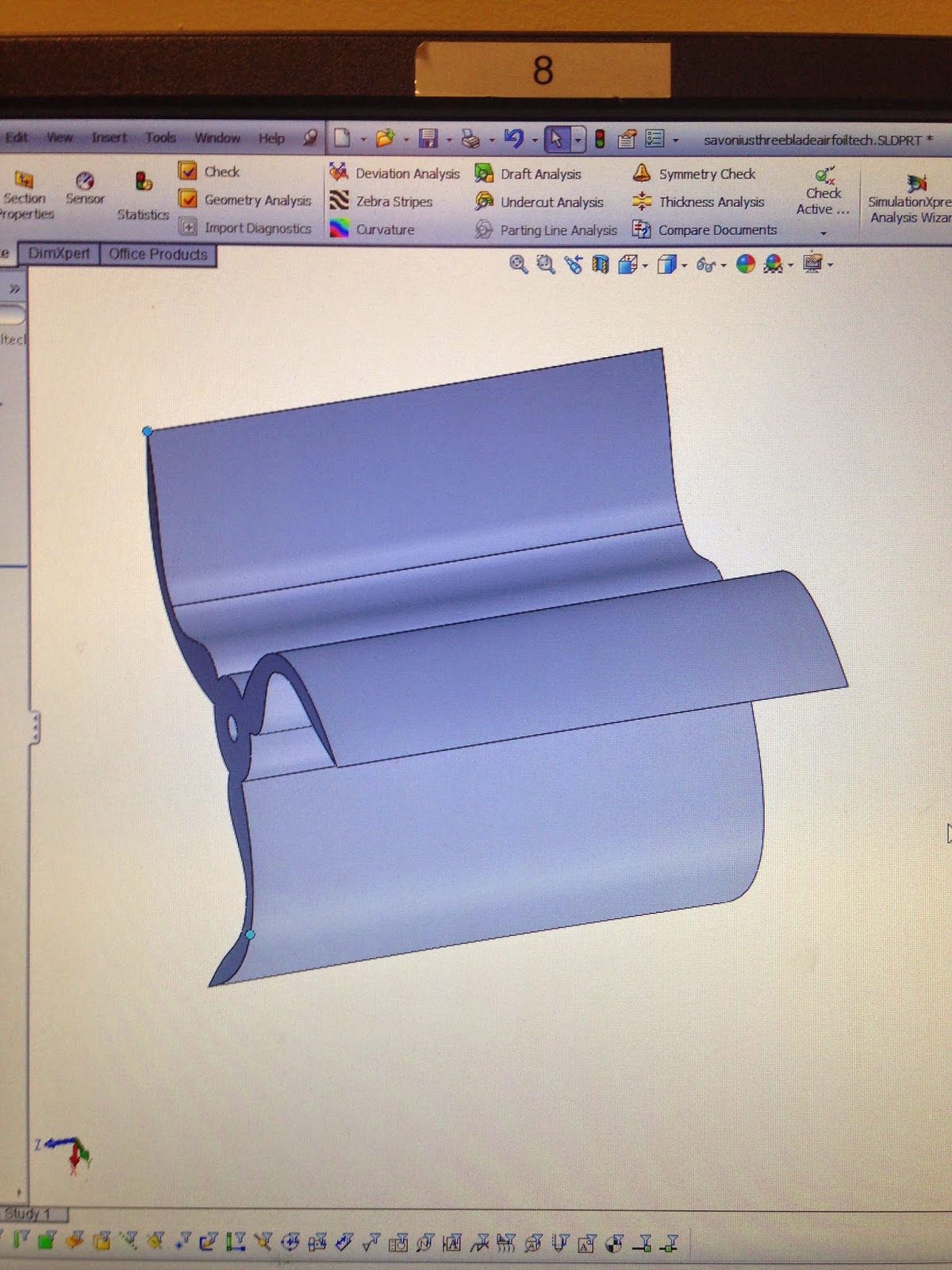

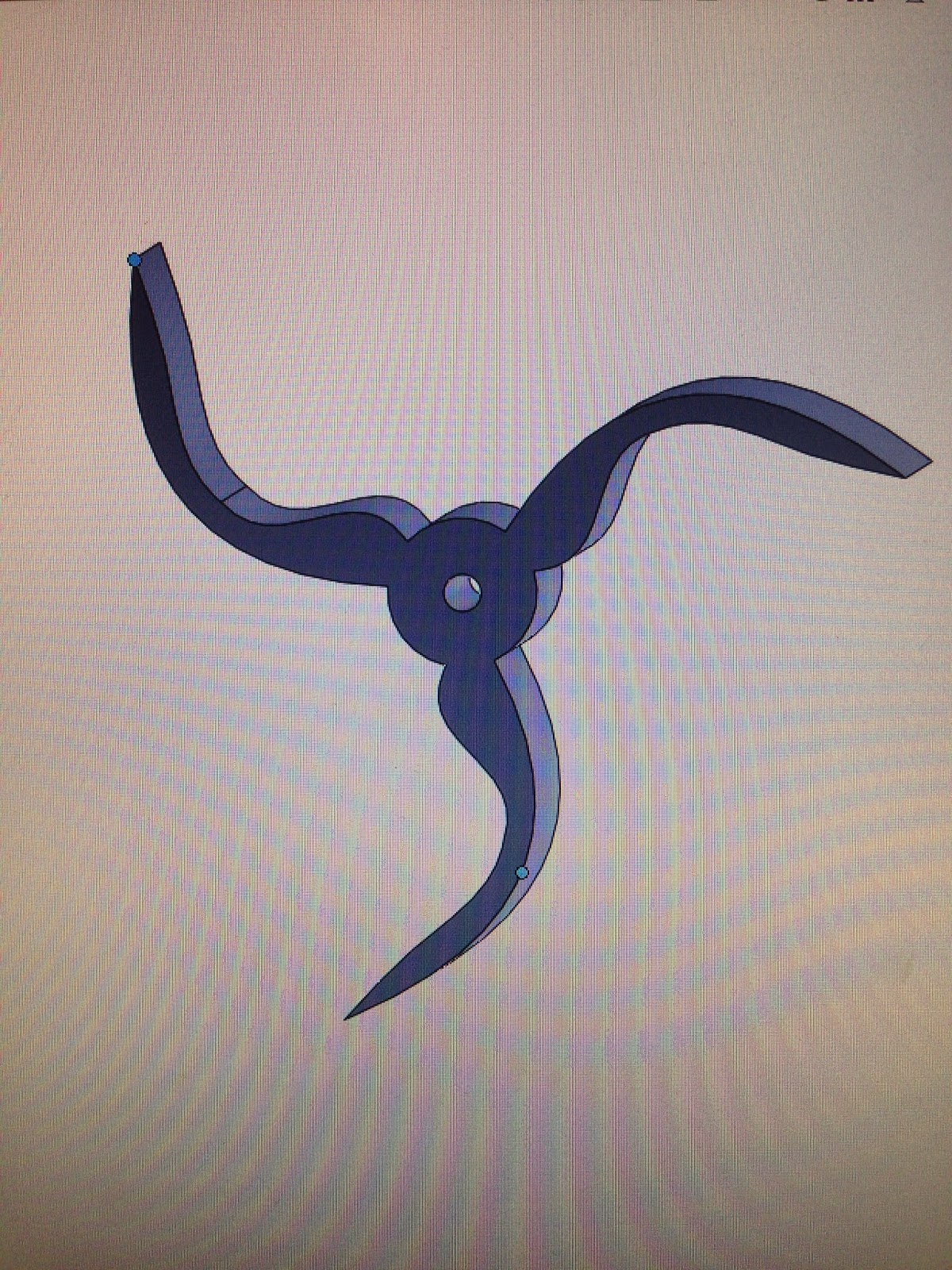

(Elizabeth) I resized the four-blade savonius design that had been printed (it was way to big to be placed within a gutter) and created a three-blade savonius design to test against the four blade design (because the blades are not removable we need some way to test the different amounts of blades against one-another). These will be printed ASAP. I thickened the blades on the Gorlov design and rescaled the turbine; however, there was an issue with the printer/file and I will work to fix this issue and print this design. I also purchased a large piece of acrylic and a plastic cutter (and some sealant/glue) that we will use to create the gutter environment.

5/12/14 (Rohun)

I continued to work on a redesign of my Gorlov design. By moving the location of the connecting pegs, I hope to create a more stable joint and thereby increase the stability of the modular turbine. I also talked with my research advisor as to the necessity of ordering parts for the generator part of the project, which will be started after winter break.

(Elizabeth) I created our FloXpress tutorial using the video that Rohun and I had shot (pending upload to the blog). I also worked to create a few other videos of the parts that have been printed for documentation purposes that will be uploaded ASAP.

update: 3 and 4 blade savonius designs were scaled down to 9.5cm (to fit into the gutter) and were printed.

11/12/14 (Elizabeth) Today I went to tech shop to cut a side out of two of our three downspout pieces and cut two pieces of acrylic. I cut a window into on of the gutters and I cut a full section out of the other gutter. First I cut and filed the two gutter/downspout pieces:

Next, I scored the cut the acrylic by scoring it and then breaking along the score lines. The acrylic will be glued to the gutter/downspout pieces ASAP.

11/12/14 (Rohun)

I continued to work on the CAD files for the turbine base, and I created a basic assembly to contain the turbine while it is spinning. I also worked with and gained a greater understanding of the magnetic field sensor.

15/12/14

Today we glued the acrylic onto the aluminum gutter downspouts. Rohun created an assembly of the Gorlov turbine inside of the gutter.

|

| Acrylic being glued to gutter #2 |

|

| Acrylic being glued to gutter #1 |

|

| Acrylic being attached to gutters |

|

| close up of printed Gorlov Turbine |

|

| Assembly of Turbine in gutter #1 |

1/8/15:

After testing the gutter assembly (see videos under "Journal"), it has been decided that we will create a more realistic gutter environment that better replicates that of a house. This environment will consist of a gutter and downspout connected to a piece of plywood.

|

| Before |

|

| After |

We also have the Gorlov-Tesla turbine finally assembled (with the inner core):

And we assembled the Savonius turbine into a simple gutter environment (first iteration of the gutter environment). The printer ran out of material while printing the Savonius so we will be re-printing it. We will be testing this environment along with the second iteration of the gutter environment ASAP.

01/21/15- Elizabeth: Today I redesigned the Savonius turbine with the light-weight air-foil designed blades of the Gorlov turbine. I designed multiple versions of the turbine, each with different numbers of blades. Once these turbines are printed, I will test them in the gutter environment that we created.

01/21/15-Rohun

So it has been awhile since I have posted anything. I finished up the funnel that will channel water for the turbine, and I created a two-bladed "bucket" savonius design. I also did some more research on hybrid turbines, and narrowed down the types of turbines we will be testing. Last week, we finished up the testing environment, and ran our first tests.

01/27/14- Elizabeth

Last class the three versions of the Savonius turbine were printed and I fit them onto dowel rods. The three blade and the four blade versions were just a bit too big to fit into the gutter system and thus, today I worked to scale down the three and four blade models. Once they are printed we will continue tests in the gutter environment, alongside the funnel that Rohun created.

02/06/15-Rohun

I finished up some basics for testing for the Generator assembly, and finalized the device that will hold the magnets in place. I also redesigned the Bucket Savonius design to allow it to fit in the downspout. Elizabeth tested some designs, and ruled out the Gorlov design as it does not function well in the downspout environment.

03/12/15-Rohun

I attempted to finish wrapping the generator housing when it failed again. The struts buckled under the force of the wrappings. I have increased the thickness of the struts, and will be revising my wrapping technique to decrease the stress placed on the housing by the wire.

03/17/15-Rohun

I came in today to finish wrapping and get data. I redesigned the housing as a solid piece, as the thin housing struts have a tendency to give in under not a lot of pressure. I also ran some simulations on the housing to determine the minimum thickness required to maintain structural integrity. I also looked into von-Mises stress yield as a way of insuring that the housing would not fail.

03/19/15-Rohun

I finished the generator housing today. To make sure that it will function as intended, I attached the ends of the housing to a DC power supply to see if a magnetic field was generated. The field was generated, so it follows that an electric current will be generated by the presence of a changing magnetic field.

No comments:

Post a Comment